Top 5 Penn Tool Co. Buyer’s Favorites Tools of 2025

Top 5 Penn Tool Co. Buyer’s Favorites Tools of 2025

2025 has emerged as a year defined by one word, resilience, in high-stakes American manufacturing. As machine shops across the country face an 8.5% year-over-year surge in demand for precision components, according to Mordor Intelligence, the margin for error has never been thinner. Automation is a necessity for every local tool and die shop looking to survive and thrive.

For over 50 years, Penn Tool Co. has stood as a cornerstone of the metalworking community. From our humble beginnings in the "Ironbound" section of Newark to becoming a global leader in precision measuring tools, machine tools, and accessories, our mission has remained consistent: empowering manufacturers to maximize productivity.

This year, buyer behavior has shifted decisively toward tools that can withstand the "harsh shop" environment, oily, dusty, and high-pressure.

In this guide, Penn Tool Co. explores the top five buyer favorites of 2025 and explains why these investments are driving profitability.

Why Upgrade?

Open PR reports that the global precision tool market is valued at $20.09 billion this year as manufacturers swap manual guesswork for data-driven accuracy. Shop floors are faster and more abrasive, making two upgrades non-negotiable for ROI:

- The IP67 Shield: Moving to IP67-rated protection, which means the tool is completely dust-tight and protected against immersion in water up to a certain depth, reduces tool failures and measurement errors. These instruments withstand immersion in oil and water, making them reliable even when standard electronics fail.

- The DRO Transformation: DRO Systems (Digital Readouts) have become the industry standard for manual machines. By eliminating "invisible" handwheel backlash, modern DROs significantly reduce measurement errors, effectively turning legacy equipment into high-precision powerhouses.

As a GSA (General Services Administration)-approved provider, Penn Tool Co. ensures every upgrade delivers NIST-traceable accuracy, providing the certainty required for high-stakes aerospace and medical manufacturing.

2025 Buyer Favorites: Top 5 Essential Tools

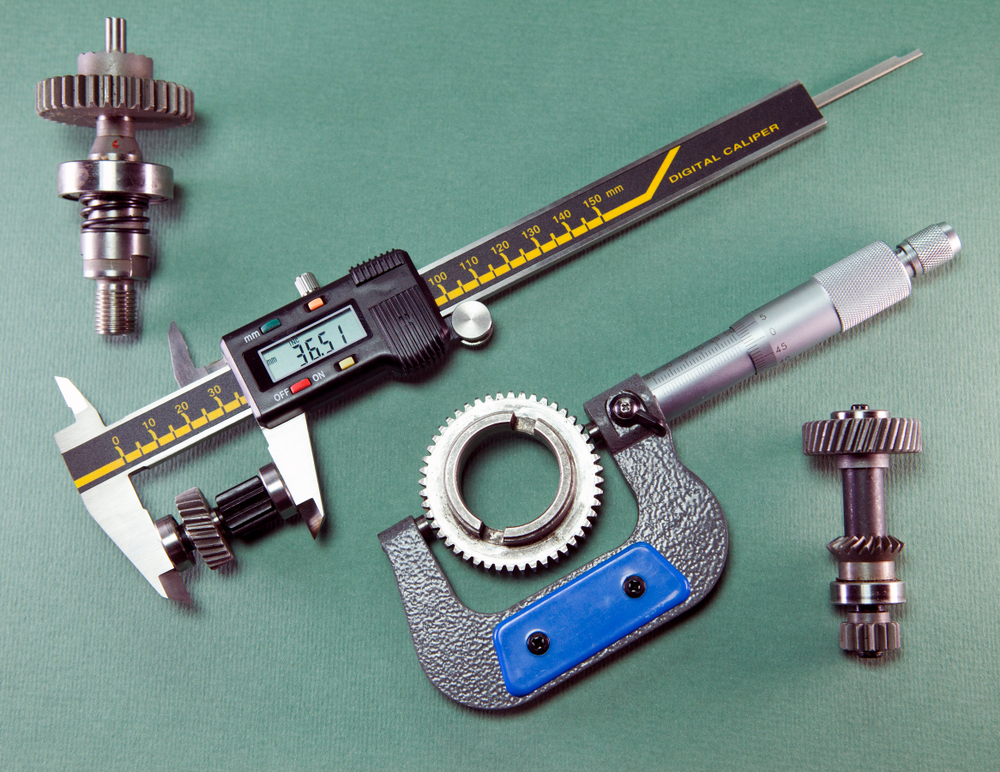

Accuracy is the currency of the machine shop. This year’s favorites represent a blend of legendary engineering, high-value precision, and the heavy-duty "muscles" required for modern manufacturing. Here are the top five tools driving productivity:

01 | SPI IP67 Digital Caliper

The SPI IP67 Digital Caliper stands out for its durability and value. Its Absolute feature retains the zero point when powered off, saving time on repetitive tasks.

- Resolution: 0.0005" (0.01mm)

- Range: Models available up to 12."

- Best For: Harsh environments where chips, dust, and coolant spray are constant threats.

02 | Mitutoyo Coolant-Proof Caliper

The Mitutoyo Coolant-Proof Caliper, with its IP67 rating and ABSOLUTE encoder, sets the bar for premium shops. It delivers reliable precision throughout demanding, high-vibration workdays.

03 | Fowler Outside Micrometer

For aerospace-grade tolerances, calipers can't match the Fowler Outside Micrometer. Buyers prefer satin chrome frames and carbide-tipped faces. With 0.0001" graduations, these micrometers deliver precise, reliable measurements. The integrated friction thimble ensures uniform pressure is applied, guaranteeing consistency across shifts.

04 | Penn Dial Test Indicator

No setup is complete without a Penn Dial Test Indicator. At a buyer-friendly price, this 0–1" model is a staple for checking runout and aligning workpieces. Its versatility makes it a favorite when paired with magnetic bases, helping in quick, accurate checks across a variety of machine tools without breaking the budget.

05 | Jet J-2550 Drill Press

The Jet J-2550 Drill Press stands out for versatility and power, with a cast-iron head and large quill for accurate, high-torque operations.

- Key Feature: A telescoping safety guard and an enclosed spindle assembly supported by four permanently lubricated ball bearings.

- Performance: With 12 spindle speeds ranging from 150 to 4,200 RPM, it handles everything from delicate plastics to heavy-duty mild steel with ease.

Buyer Tips: Maximizing ROI in Your Workshop

Investing in top-tier brands like Mitutoyo, SPI, or Jet isn't just about the name; it’s about the return on investment (ROI). Here are three tips to ensure your tools last a lifetime:

- Prioritize Ingress Protection: If you work with coolants, don't settle for "water-resistant." Go for IP67, meaning the tool is completely dust-tight and can withstand immersion in water. The extra $50 upfront will save you $200 in replacement costs when the tool is inevitably splashed.

- Calibration Matters: Ensure your measuring tools are NIST-traceable if you are working in the medical or aerospace sectors. Penn Tool Co. offers a range of tools that meet these rigorous standards.

- Invest in Storage: A Fowler Outside Micrometer or an SPI IP67 Digital Caliper is a precision instrument. Protect that investment with quality tool chests; brands like Kennedy (made in the USA) are still the favorite.

Conclusion: Driving Profitability Through Precision

Today’s tools are smarter, tougher, and more connected than ever before. Whether you are upgrading a manual mill with a new DRO System (Digital Readouts) or outfitting a quality control lab with Mitutoyo Coolant-Proof Calipers, the goal remains the same: accuracy that drives profit.

At Penn Tool Co., we take pride in being more than just a supplier; we are a partner in your manufacturing journey. With over 250,000 products and a legacy of collaborative customer service, we are here to help you navigate the complexities of modern metalworking.

Shop our buyer favorites today or contact us for a GSA quote.

Frequently Asked Questions

- What makes the SPI IP67 Digital Caliper a top choice for 2025?

Its primary appeal is the combination of IP67 protection and high resolution (0.0005") at a competitive price. In modern shops where coolant and metal chips are everywhere, the chip-proof and dust-proof design ensures a much longer lifespan than standard electronic calipers.

- How do Mitutoyo Coolant-Proof Calipers reduce operator error?

The ABSOLUTE encoder technology means the caliper "remembers" its zero position. Even in heavy-duty environments with oil and water, the sensor doesn't lose track of its position, eliminating the need to constantly re-zero the tool and preventing costly reading mistakes.

- Why is the Jet J-2550 Drill Press considered a stable investment for heavy-duty work?

The Jet J-2550 features a heavy cast-iron head and a ground-steel column, which minimizes flexing under load. Its large quill diameter and permanently lubricated ball bearings provide the rigidity needed for high-torque drilling, ensuring that holes remain true even in the toughest materials.