14th Nov 2023

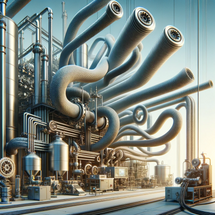

Elasticity in Engineering: Embracing Flexible Tubes for Robust Industrial Solutions

The industrial landscape is marked by the constant push and pull of innovation and functionality. Among the unsung heroes paving the way for this progress is the humble flexible tube. From factory floors to hospital hallways, their ubiquitous presence is a testament to their indispensable role in modern-day applications. This blog aims to spotlight the myriad benefits of flexible tubes, underscoring their significance in today's fast-paced, ever-evolving industrial setups.

1.) A Symbol of Resilience: Durability and Resistance

Industries demand components that weather various operational challenges, from temperature spikes to exposure to aggressive chemicals. Step in flexible tubes, crafted from silicone, antimicrobial plastics, and Teflon, offering unparalleled durability. Their inherent flexibility makes them adept at adapting to machinery dynamics, thereby reducing the strain and subsequent wear and tear that their rigid counterparts might experience.

2.) Commanding the Flow: Enhanced Flow Control

The fluidity of operations in industrial settings often hinges on the literal flow of fluids and gases. Flexible tubes, devoid of kinks or blockages, promise an unobstructed flow. The reduced friction, coupled with the option to customize tube specifications (like diameter and length), ensures that industries can maintain a consistent, smooth flow integral to their operations.

3.) Seamless Integration: Ease of Installation and Maintenance

Complex machinery and tight spaces are standard across industries, emphasizing the need for components that can weave through such intricacies with ease. The moldability of flexible tubes ensures they fit into any setup seamlessly. Their modular nature, complete with tailored fittings and adapters, simplifies installation and maintenance processes, translating to substantial time and cost savings.

4.) Universal Utility: Versatility Across the Board

The reach of flexible tubes spans a wide spectrum of industries - from automotive and aerospace to biotech and healthcare. Their adaptability, combined with features like high-pressure resilience and chemical resistivity, makes them a mainstay across varied applications and environments.

5.) Efficiency Meets Affordability: Cost-Effective Solutions

Beyond their operational advantages, flexible tubes emerge as a fiscally prudent industry choice. Their longevity means fewer replacements and their efficient design translates to reduced maintenance efforts. The cumulative effect is minimized downtime, heightened productivity, and reduced operational expenditure.

As industries evolve, the components driving their operations must keep pace. Flexible tubes, with their myriad advantages, stand as a testament to how simple engineering solutions can have profound, wide-reaching impacts. Their presence across industries, from the intricacies of biotech labs to the vastness of aerospace applications, is a resounding endorsement of their utility and efficiency. For industries aiming to future-proof their operations, embracing the flexibility of these tubes is not just an option; it's a necessity.

Discover the ideal tubing solutions for your projects at Penn Tool Co. Our range of tubes is designed to meet the diverse needs of various industries, from automotive to aerospace. These tubes are crafted for durability, precision, and versatility, ensuring they can handle even the most demanding applications. Whether you need flexible tubing for fluid transport or rigid tubes for structural support, we have options to fit every specification. Browse our selection and find high-quality tubes that deliver reliability and performance.