13th Apr 2021

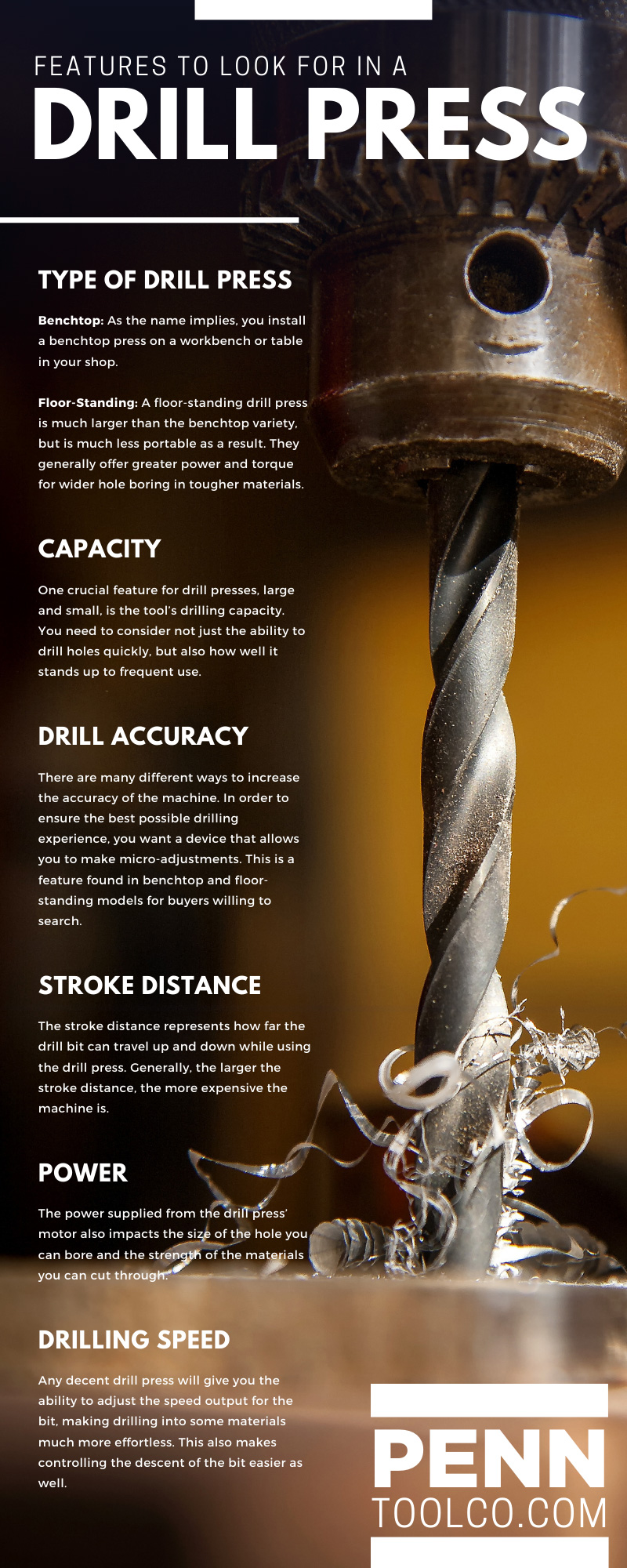

Features To Look for in a Drill Press

Features to Look for in a Drill Press

The drill press is one of the most useful tools in nearly every workshop. This machine is fantastic for boring holes in both metal and wood, which speeds up the drilling process.

But, how do you find the right one for your operations? With the machine capable of producing many different hole sizes and angles, finding the best option for your shop can be challenging.

Fortunately, at Penn Tool Co., we’ve been curating, using, and comparing industrial drill presses for over 50 years! Here is a closer look at the essential features to look for in a drill press before you make a purchase.

What Type of Drill Press Do You Need?

There are different types of drill presses, so this is the first thing you must decide when purchasing a drill press. The two main styles of a drill press to consider are benchtop and floor-standing.

Benchtop Drill Presses

As the name implies, you install a benchtop press on a workbench or table in your shop. These machines typically come with a heavy base to prevent the tool from moving during operation.

This style features some of the most popular benchtop variations, including radial, hand, magnetic, and mini drill presses. Typically smaller than their floor-standing brethren, benchtop drills work best on small-scale projects.

Floor-Standing Drill Presses

A floor-standing drill press is much larger than the benchtop variety, but is much less portable as a result. They generally offer greater power and torque for wider hole-boring in tougher materials.

This utility does come at a premium, as floor-standing machines are nearly always more expensive than benchtop models. They also take up more space, making them a better fit in a professional environment.

What Should You Look for in a Drill Press?

Once you’ve determined the right type of drill press for your business, you can begin comparing drill press features. The most vital of which include:

- Capacity

- Drill Accuracy

- Stroke Distance

- Power

- Table Specifics

- Drilling Speed

- Chuck Type

Capacity

One crucial feature for drill presses, large and small, is the tool’s drilling capacity. You need to consider not just the ability to drill holes quickly, but also how well it stands up to frequent use. Remember that bigger machines usually handle larger loads better, but are also less portable and more expensive.

What is Meant by the “Capacity” of a Drill Press?

The capacity of a drill press refers to the greatest diameter that a drill press can bore into a particular material.

Drill Accuracy

The drill’s accuracy is also essential, especially when working with delicate materials. There are many different ways to increase the accuracy of the machine.

In order to ensure the best possible drilling experience, you want a device that allows you to make micro-adjustments. This is a feature found in benchtop and floor-standing models for buyers willing to search.

Even for larger projects, there are drill press options that allow for incredible accuracy with a floor-standing model. Remember to compare the accuracy benefits of each machine.

Stroke Distance

The stroke distance represents how far the drill bit can travel up and down while using the drill press. Generally, the larger the stroke distance, the more expensive the machine is.

But as the distance grows larger, so does the thickness of the material you can safely bore. A larger stroke distance also makes it easier to work with bits of different sizes, saving time and providing options.

Power

The power supplied from the drill press’s motor also impacts the size of the hole you can bore and the strength of the materials you can cut through. For example, larger bits often require a press with more power to drill into the objects.

Ensuring you have enough power is especially important when your drilling needs also include going through metal periodically. While heavy-duty models exist with 1+ horsepower, most workshops can get away with a model boasting 1/2 or 2/3 horsepower.

Table Specifics

There are also several table features to look for in a drill press. The table must hold up to the heavy use while still offering the versatility to handle even the most demanding tasks. The two most essential table options to consider when looking for a new press are the table’s size and the tilt.

Size

The bigger the projects you intend on completing, the larger the table you want for your drill press. Obviously, larger tables are also helpful for holding your materials and provide a better view than if you tried boring on a smaller surface. A table gets bonus points if you can move its height up and down to allow for better access.

Tilt

Another critical feature for a drill press table is the ability to adjust the tilt. There will be times when working on a project where you will need to bore a hole at an incline.

This is where the table’s tilt comes in. It controls your ability to modify the entry point of the bit, enabling you to drill holes at different angles.

Drilling Speed

Drilling speed is another feature to look for when purchasing a new drill press —or rather, the ability to control the drill speed. Any decent drill press will give you the ability to adjust the speed output for the bit, making drilling into some materials much more effortless. This also makes controlling the descent of the bit easier as well.

Chuck Type

The type of chuck you have will determine the bits you can use and how you go about changing them. The two main chuck types found on drill presses are keyed and keyless.

Keyless

A keyless chuck takes less time to change and is generally less complex. But this simplicity comes at a premium, as these are usually more expensive than their keyed alternative. It can also be a challenge for some keyless chucks to secure the bit in place with the same tightness of a keyed option.

Keyed

A keyed chuck is excellent for securing your drill bit in place, and many provide built-in storage for the key. The biggest drawback to having a keyed chuck is the possibility of losing the key.

There are many clever means for resolving this, including keeping the key on a string tied to the machine and hanging a hook for the key to be stored on when not in use. Even if you lose it, many keys are a universal size, so you might be able to use the key from another drill chuck.

Find a Drill Press with the Best Features at Penn Tool Co.

At Penn Tool Co., we offer a wide variety of drill presses, each with unique features to fit your needs. If you’re in the market for a drill press, be sure to check out our selection!

More importantly, we know you have many questions that arise when buying a new drill press machine. Fortunately, our team is available to answer any questions and help find the perfect tool for your shop.

For help comparing and selecting the best drill press machine for your workshop, reach out to our team today.