Posted by Penn Tool Co., Inc on 25th Aug 2021

Types of Coolant To Use for a Lathe Machine

Types of Coolant To Use for a Lathe Machine

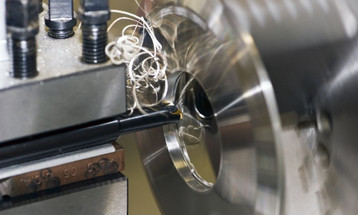

Lathe machine operators know that their work causes quite a bit of friction. So much, in fact, that they rely on machine coolant to keep their operations safe.

Coolant for lathe machining is vital for minimizing friction, flushing away bits of the workpiece, and preventing the dangerous build-up of excess heat. In fact, proper lubrication protects your workpieces and tools against corrosion.

But how do you know which lubricant is best for your lathe cooling system? Fortunately, the experts at Penn Tool Co. sat down to consider the best options for lubricating your lathe.

The Best Types of Coolant for Machining

Seeing the variety of coolant options in the metalworking and machining industries, you may find it hard to decide which is best. Start by narrowing down the job and tool that you’re using.

If you’re looking for coolant to use for a lathe machine, you’ve already narrowed down the long list of options, but there are still a few choices to make. The main two coolant options in machining are:

- Oil-Based Coolants

- Chemical-Based Coolants

Each has its own unique qualities, applications, and advantages. Below, we discuss these differences to empower you to find the perfect lathe machine coolant systems for your operations.

Soluble Oil Based Coolant

Oil-based coolants are some of the most popular coolants that people use in machining. In fact, when talking about coolants in machining terms, many operators often think of oil-based coolants first.

This type of coolant can have a pure oil base or an emulsion. An emulsion is a mixture of water and oil, and there are many different ratios for water to oil in emulsion coolant mixtures.

Oil-based machine coolants provide a good “cushion” between your tool and your workpiece. Alternatively, they may not dissipate heat as effectively as some chemical-based lubricants.

Chemical-Based Coolants: Synthetic Fluids & Semisynthetic Fluids

Chemical coolants aren’t as popular for use in metalworking and machining. People frequently use chemical coolants in other fields, such as automotive work.

Antifreeze is an example of a chemical coolant, which works with engine parts. Chemical machine coolants also include various synthetic and semi-synthetic coolants, which people are more likely to use in machining.

How to Choose a Lathe Coolant

Your choice regarding the right coolant for your lathe machine depends on several factors. You will need different coolants based on the machining process you perform and the materials you work on.

Milling, drilling, tapping, and turning are all lathe machine processes that require unique coolant types. For example, when drilling brass, bronze, and alloy steels using a lathe, you want to use a soluble oil coolant.

However, it’s best to use a 70-90% water-to-soluble oil ratio when drilling aluminum. Make sure to research which materials are most compatible with each coolant before selecting one.

Why it’s Important to Select the Right Machine Coolant

Whether you use a speed, automatic, or bench lathe machine, you should pay attention to the type of coolant it needs.

The utilization of the right coolant is crucial to prevent fires, keep your lathe from overheating, and maintain the tool.

Use this guide on the types of coolant to use for a lathe machine to understand what’s best for your equipment.

Find the Best Machining Coolant at Penn Tool Co.

Proper lubrication prevents damage to your tools, mistakes in the workpiece, and potential harm to operators. However, there are many different types of coolant that can be used in a lathe cooling system.

With so many diverse applications, it can often feel overwhelming to pick the perfect fit for your operations. Fortunately, at Penn Tool Co., we have over 50 years of experience in the machining and manufacturing industries.

This means that we’ve had the opportunity to conduct trial-and-error tests so that you don’t have to. To take advantage of our experimentation and find the best lathe coolant for your shop, reach out to our team today.