21st Jul 2017

3 Reasons Why Calibration of Your Measuring Instrument is Important

3 Reasons Why Calibration of Your Measuring Instrument is Important

In contemporary times, we are surrounded by technology. Our entire world revolves around it, without which none of our work seems to be possible. Accuracy becomes the most important factor when it comes to using machines as the reliability of production totally depends on the advanced technology of the machines. For this purpose, it becomes indispensable to look for the specifications of the measuring tools used to check the precision and accuracy.

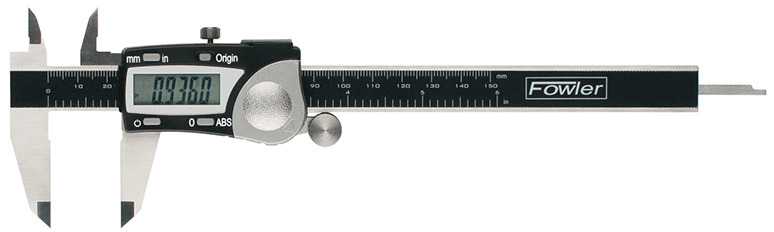

Numerous

precision measuring tools are used to ensure that the machines serve us with the correct data. These instruments need to be accurate enough on which one can rely on taking decisions and performing tasks. Due to this reason, calibration of measuring tools are done to assure that the measurements are appropriate and deliver correct information.

What is Calibration?

A process of juxtapositioning between a standard measurement and one which is used for measuring is termed as calibration. It configures an instrument, providing assurance that the result delivered is appropriate.

When it comes to checking the precision of instrument through calibration, it should be 10 times the accuracy of the measuring device that is being compared with standard one. If there arises a case where measurements don’t meet expectation to that of the criteria, then with the help of calibration it is adjusted for achieving particular specifications.

Why is Calibration Important?

It serves us as a guarantee that tool which is used for the measurement is meticulous. For better understanding, we brought you few more reasons that would evidently explain its paramount value.

No Manufacturing Errors, No Cost

Sometimes, large manufacturing industries may face some flaws in the production. Consequently, the cost of it rises. Though defects would be small, their costs prove to be the high burden on the manufacturers. It would not only be expensive in the form of resources, but also as a waste of time. It can be avoided through calibration of measuring instrument that verifies if it delivers an appropriate result or not.

Calibrating tools and gauges will evidently reduce the risk for attaining any possibility of production defects. But, ensure that the sensors which are used for its monitoring are appropriate in this process. However, laying hands on the correct calibrating tools would serve your purpose in the best way and it can be done by buying it from a trustworthy supplier such as Penn Tool Co. For gaining detailed information, you can explore penntoolco.com and get your desired products.

Safety

It goes without saying that when every functioning of the measuring instruments is verified under the process of calibration, it keeps all the processes safe. All the devices and machines which are used to produce products ensures its safety through this process.

Certification

The accuracy of measuring device deteriorate with time fleets. And this wear and tear of the machine are occurred due to several factors affecting it. Therefore, it becomes imperative to look for the safety of it, which can be made possible by calibrating measuring tools proficiently. However, it can be said that certification of the machine is maintained through calibration.

Now since you are introduced to the paramount importance of calibrating instruments, it is upon you whether or not to consider these points in your manufacturing process. Besides, it is for sure that this verification process won’t harm the production in any way.